The design of XENDOLL student safety machine tools spans from vocational skill training to hobby cultivation, providing students with hands-on skills and innovative thinking patterns.

The design of XENDOLL student safety machine tools spans from vocational skill training to hobby cultivation, providing students with hands-on skills and innovative thinking patterns.

It is equipped with an industrial-grade CNC system, applicable to internationally programs, with automatic fault detection and alarm functions, and power-off memory function.

Milling machines, known for high processing accuracy, good surface quality, and strong adaptability, are widely used. However, different part structures suit different machining methods. For milling machines, the most suitable part structures are as follows.

The machine body is cast from high-quality cast iron, then quenched and precision ground to ensure machining rigidity and accuracy, making it sturdy, stable and durable.

In the field of mechanical processing, metalworking typically involves a series of complex steps aimed at transforming raw materials (such as metal bars and sheets) into the required parts or products.

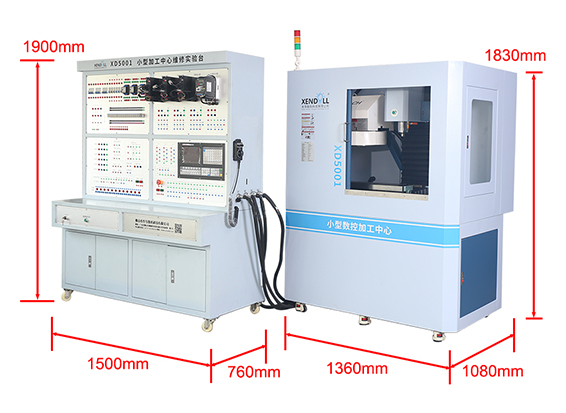

The XD5001 CNC machining center repair lab bench is a multifunctional teaching platform combining mechanical processing, electrical control training, fault diagnosis, and CNC system training.

It can also be used by educational training institutions and enterprise engineers, graduate students for industrial 4.0 intelligent unmanned factory setup training and advanced comprehensive learning and training.

A machining center is a numerically - controlled machine tool with a tool magazine that can automatically change tools.

CNC technology falls under the category of equipment manufacturing, aiming to cultivate well-rounded individuals with solid scientific and cultural foundations, CNC program compilation, production organization, and quality management.

The translation of the small CNC milling machine operation tutorial

In today's rapidly evolving manufacturing industry, CNC lathe technology has become an essential part of modern industrial production. As a professional who has long been engaged in the operation of CNC lathes, I am well aware of the significance of this technology.

In traditional vocational education, mechanical processing courses often remain at the level of theoretical explanation or simple manual operations, making it difficult for students to deeply understand the entire process of digital manufacturing.