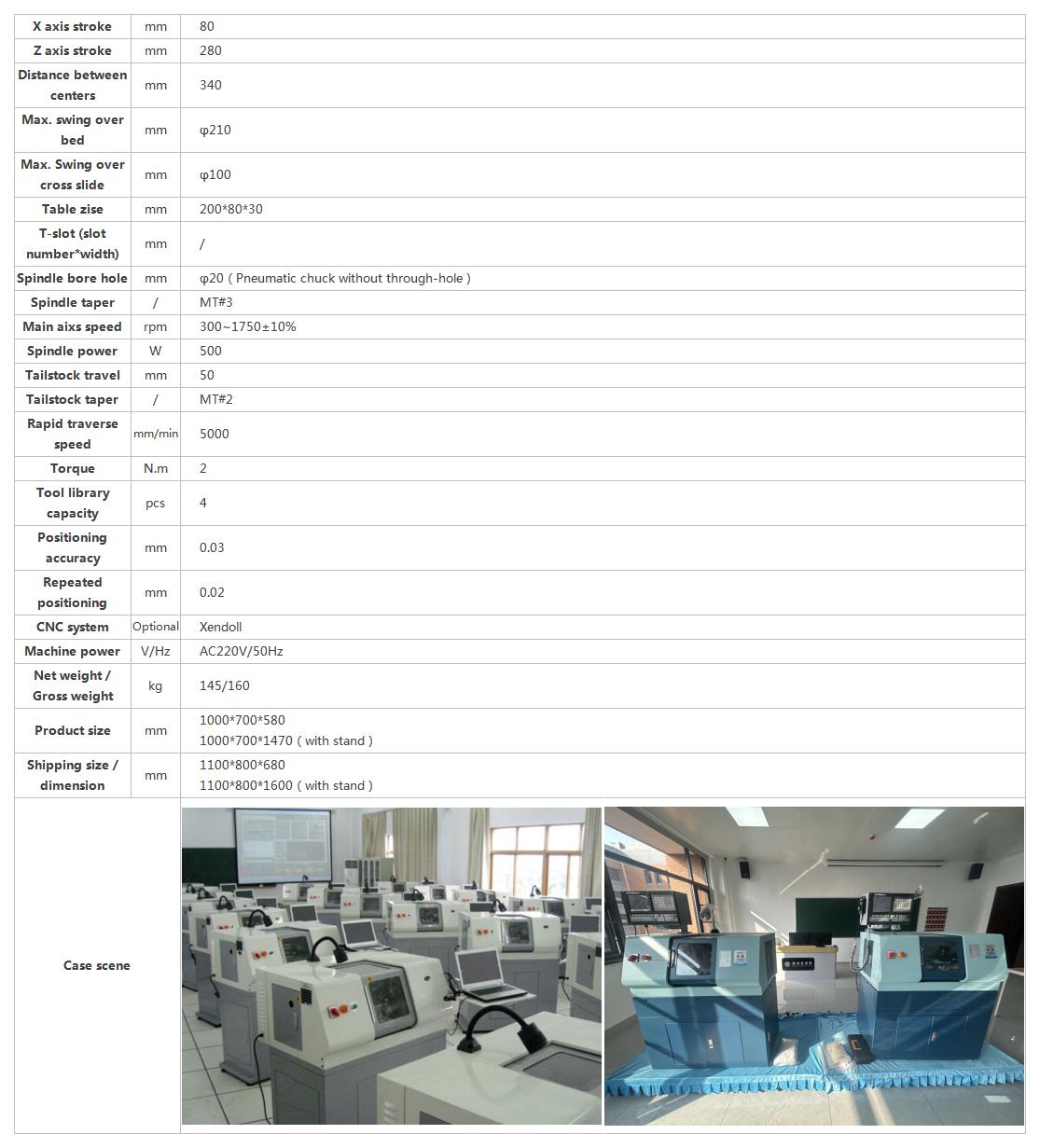

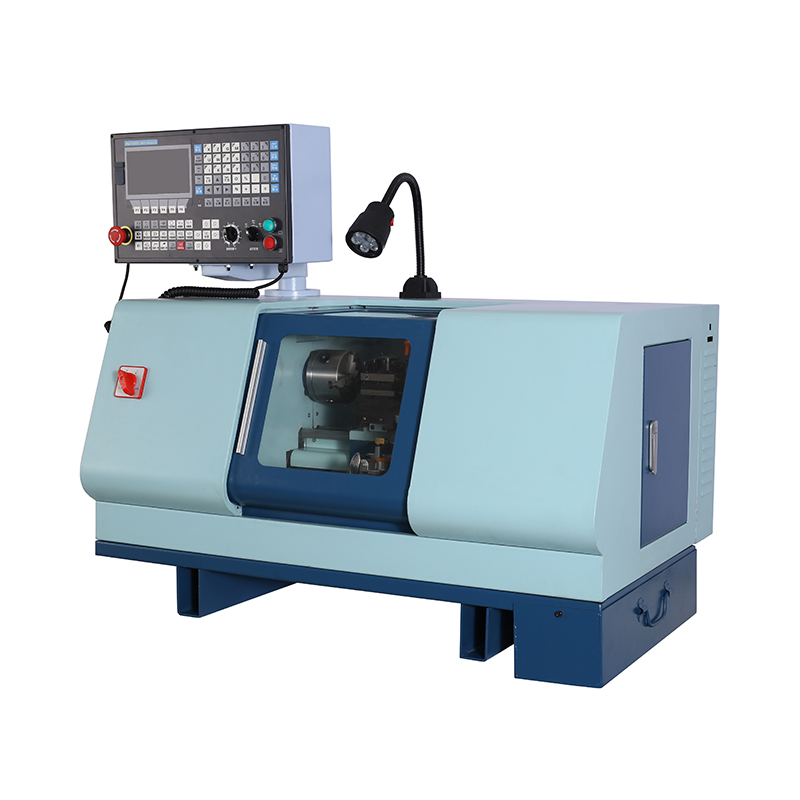

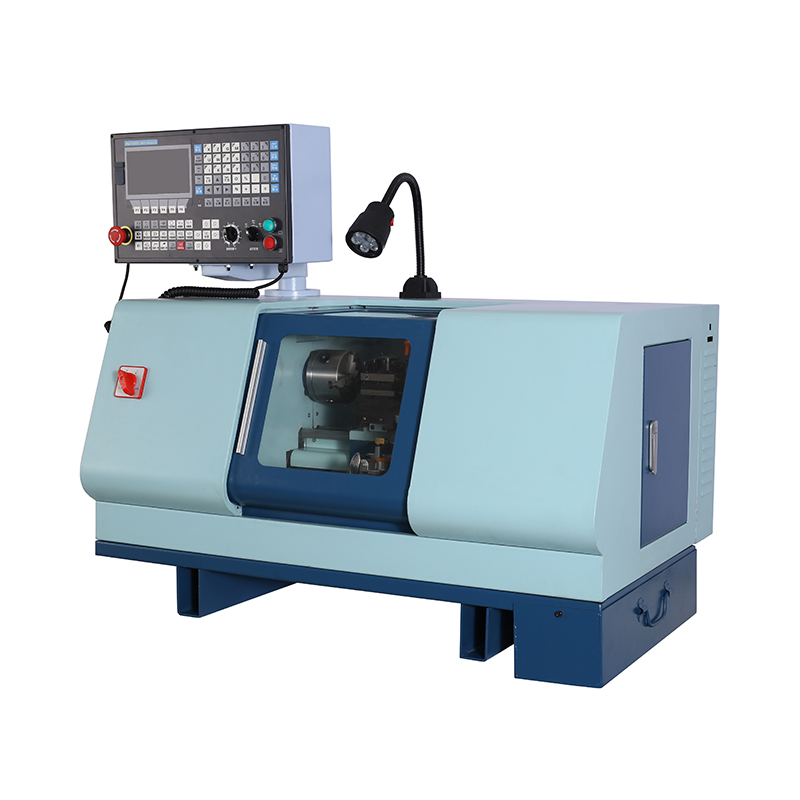

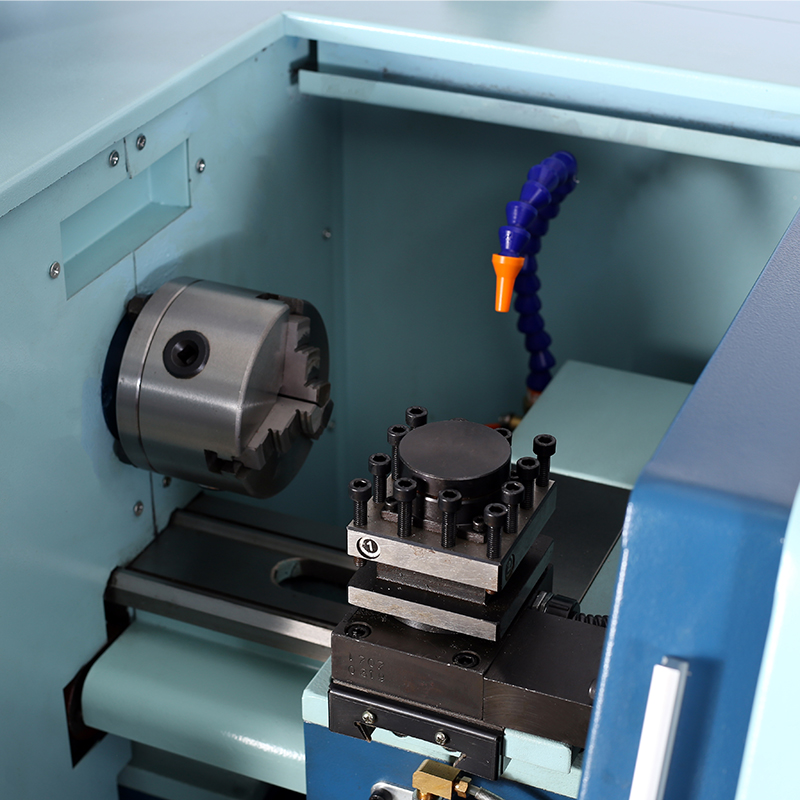

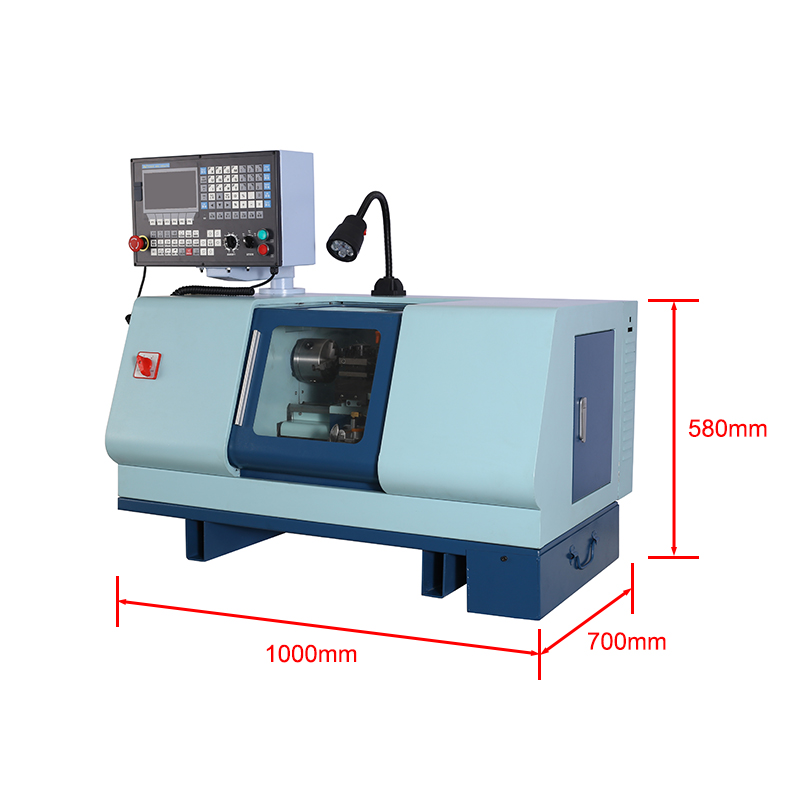

Xendoll CNC lathe system, ball screw, small volume, high precision, stable performance and reasonable price. Servo positioning control, fast and accurate positioning, four-station electric tool rest can realize complex workpiece processing, it's the ideal choice for small parts processing. front or rear pneumatic chuck, automatic feeding device. According to industry 4.0 configuration automation transformation, multiple machines can carry out centralized management and monitoring, with a variety of communication methods for data exchange, upper computer program interface can be independently developed by customers, simple and convenient, with FMS compatibility, the ideal choice for universities to study flexible processing.