Add Date: 2024/1/25 Views: 555

Keyword:#Desktop mini CNC milling machine,#Desktop mini CNC machine tool,#Desktop mini CNC lathe,#Mini CNC machine , #Teaching CNC machine

The market for CNC machine tools is huge, with a wide variety of types and high costs, leading to the emergence of small machine tools. Compared with traditional machine tools, small machine tools are more suitable for use in educational schools, factory sampling, laboratory production, and other occasions, with a large customer base.

Due to structural and manufacturing process reasons, traditional machine tools may encounter some problems during the production process, which may affect the progress of production and cause significant losses in various aspects. However, small CNC machine tools can greatly reduce your costs and enable you to produce your products more quickly and conveniently, thereby improving production efficiency.

Compared with traditional machine tools, the advantages of small CNC machine tools are mainly reflected in the following three aspects. Firstly, they adopt a digital operating system. When people operate them, they no longer need to stand next to the machine tool like before, but only need to input the established program on the operation screen to carry out the operation program; The second is to improve production efficiency, facilitate operation, reduce labor intensity, and also increase the safety factor of production; The third factor is the precision of machining. Small CNC machine tools adopt a digital control system and use cutting functions. Based on digital settings, the resulting results make the product more effective and produce parts with small and uniform surface roughness values.

The biggest feature of a small CNC lathe is that it mainly uses a chuck to clamp the workpiece. This method is particularly suitable for clamping small batches of workpieces. It only requires the action of a push handle to complete the clamping of workpieces. The clamping speed is less than one-third of that of manual chuck clamping, and even much faster than that of hydraulic chuck clamping. A skilled worker is usually able to operate 2-3 machine tools together.

Xendoll focuses on the development and manufacturing of desktop small CNC machine tools, with 20 years of experience as a senior source manufacturer of CNC products. The products are exported to domestic and foreign markets, penetrating multiple industries, mainly targeting CNC programming and applications for primary and secondary schools, vocational schools, and vocational colleges, as well as factories for sample making and small batch production of scientific research units. The leading digital small CNC lathe series is diverse and can be customized according to customer needs to meet the needs of different customers.

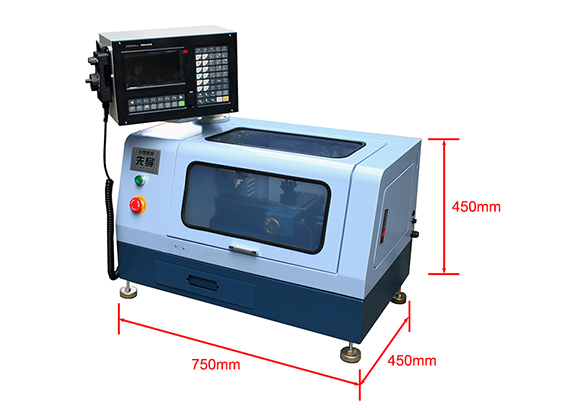

Small CNC lathe C56

Technical parameters:

|

positioning accuracy |

0.03mm |

|

Repetitive positioning accuracy |

0.02mm |

|

X-axis travel |

70 mm |

|

Z-axis travel |

160 mm |

|

Effective size of workbench |

130mm*85mm |

|

Fast movement speed |

5000mm/min |

|

programming software |

MasterCAM、UG、CAXA |

|

Spindle speed |

100-2000 rmp±10% |

|

Maximum turning diameter |

140mm |

|

Maximum clamping diameter |

70mm |

|

Electronic handwheel |

4-axis three speed electronic handwheel |

|

Knife holder |

Manual tool holder |

|

Spindle motor power |

150W |

|

Net weight |

50kg |

|

Size |

750mm*450mm*450mm |

Desktop CNC lathe C59

Technical parameters:

|

X-axis travel |

90 |

|

Z-axis travel |

295 |

|

Main spindle through-hole |

26 |

|

Spindle motor power |

1.1KW |

|

Spindle speed |

300~1750r/min((Stepless speed regulation)) |

|

Maximum clamping size of chuck |

φ100mm |

|

Maximum turning diameter |

φ210mm |

|

Fast movement speed |

Z轴6000mm/min |

|

X轴6000mm/min |

|

|

Maximum torque of X-axis stepper motor |

2.2N/m |

|

Maximum torque of Z-axis stepper motor |

2.2N/m |

|

Tail seat travel |

50mm |

|

positioning accuracy |

0.02mm |

|

Repetitive positioning accuracy |

0.01mm |

|

Tool change function |

4-station automatic turret |

|

Net weight |

280KG |

|

Size |

1300X900X800mm 1300X900X1530mm((including base)) |

Small CNC lathes can process parts with low surface roughness, but not only because of their good rigidity and high manufacturing accuracy, but also because the surface roughness depends on the feed rate and cutting speed when the material, precision machining allowance, and tool have been determined. CNC lathes are also suitable for turning parts with different surface roughness requirements. For parts with low roughness, the method of reducing feed rate can be used. Choosing XENDOLL desktop CNC allows you to have more infinite possibilities.