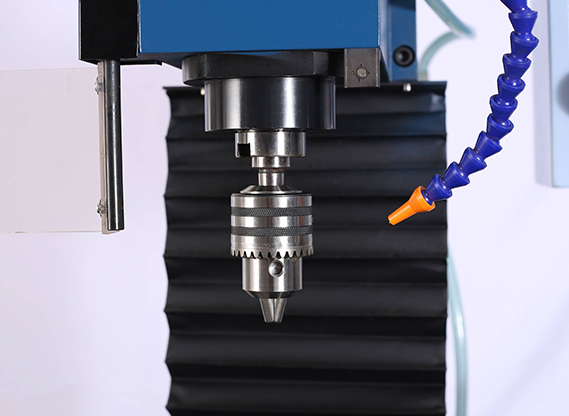

Compared with large machining centers, small machining centers have a small footprint, making them suitable for use in factories or workshops with limited space.

Compared with large machining centers, small machining centers have a small footprint, making them suitable for use in factories or workshops with limited space.

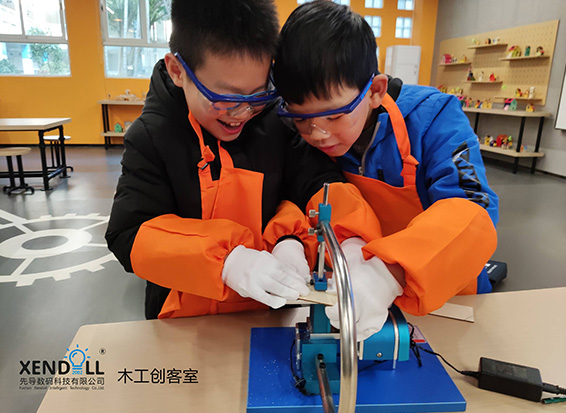

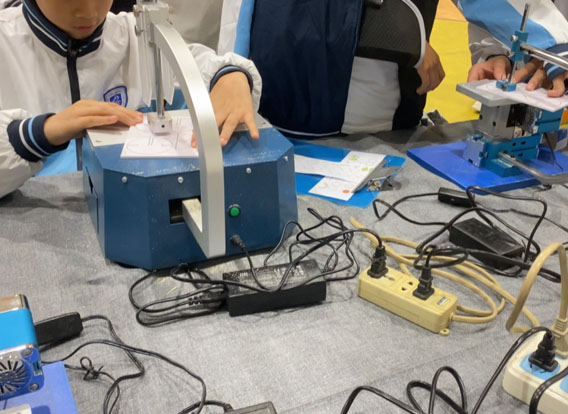

Machine tools are not merely tools but bridges in engineering education. They enable students to transition from "knowing" to "doing," cultivating practical capabilities, innovative thinking, and professional competitiveness suited for the future industrial landscape.

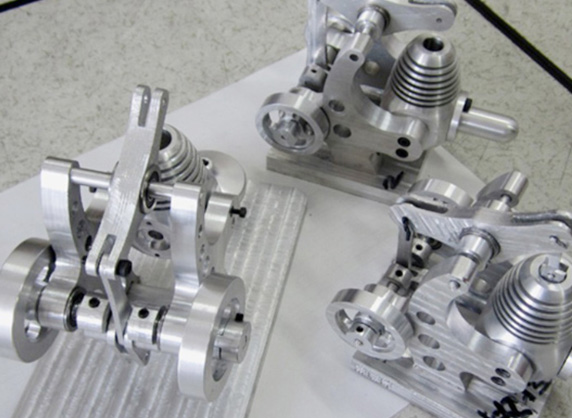

In the current trend of intelligent and precision - oriented development in the manufacturing industry, CNC machining technology has become an indispensable core technology in numerous fields such as mechanical manufacturing, electronic information, and aerospace.

In the field of modern manufacturing technology, CNC lathes stand out as a symbol of technological advancement. Students are now immersing themselves in the world of CNC lathe learning, embarking on a journey filled with exploration and growth.

What components make up a CNC system? It includes a computer, controller, servo system, and sensors.

Using safety power, no plastic parts mean higher stability and durability. With a blade aid, it extends blade life and makes use easier.

Professional saw beds like the XENDOLL W801 come with safety features like guards and emergency stop buttons, reducing operational risks. Mechanical cutting minimizes physical strain and distractions from manual operations, indirectly enhancing safety.

As the aging society accelerates, to address the needs of our time, our company participated in a public welfare activity at a nursing home this Monday.

Laser engraving machines are suitable for non-metal materials such as wood, acrylic, and leather. They cater to various groups, including individual consumers, corporate clients, and educational institutions, with applications ranging from personalized customization and industrial processing to educational uses.

Sanding tools can also be categorized based on their specific applications, such as woodworking, metalworking, stoneworking, automotive surface sanding, and furniture refinishing.

Help you design a woodworking classroom environment that ensures safety while promoting students' creativity and hands-on skills. Provide a variety of materials and tools, such as wood chips, sticks, and small saws, for students to freely choose and operate.