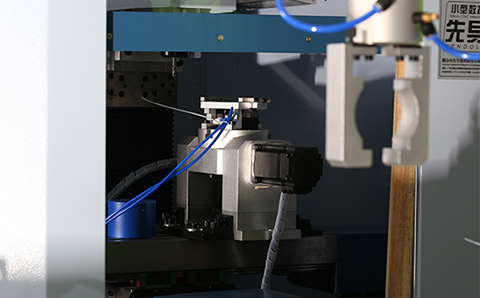

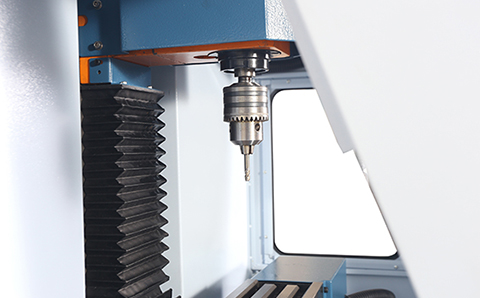

XENDOLL desktop machining center is commonly used in scientific research institutions in universities for the processing of first boards, samples, and small batch products. It can achieve various processing operations, including milling, carving, and other processes.