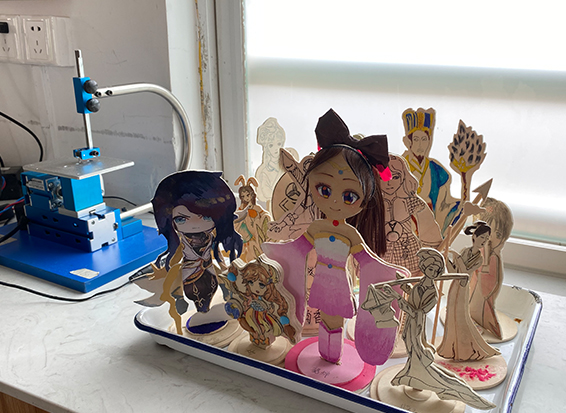

By participating in specific technical projects or practical activities, such as woodworking, metalworking, and other handmade projects, students' hands-on ability and innovative thinking are cultivated through these activities, and technical knowledge is learned and mastered through practice.