Add Date: 2025/4/8 Views: 1

Keywords: # Sanding Tools, # Primary and Secondary School Labor Skills Course, # Woodworking Education Equipment, # Woodworking Student Machine Tool, # Woodworking Creative Course

Sanding tools can be categorized based on different dimensions such as power source, purpose, and shape. Manual tools and power tools represent the most basic classification: manual tools are suitable for delicate operations, while power tools are ideal for scenarios requiring high efficiency. Based on their purpose, sanding tools can also be divided into those designed for use on metals, wood, stone, and other materials.

The variety of sanding tools is extensive, and they can be classified into manual and power sanding tools depending on their purpose, power source, and method of operation.

Types of Sanding Tools

Based on their purpose, power source, and method of operation, sanding tools can be categorized as follows:

Manual Sanding Tools

Sandpaper: Used for manually sanding surfaces of wood, metal, plastic, etc., to remove burrs and smooth surfaces. Classified by grit size (e.g., 80-grit, 120-grit, 240-grit), with higher grit numbers indicating finer particles and smoother finishing results. Commonly applied in woodworking, automotive repair, and furniture refinishing.

Sanding Belts: Typically used with belt sanders, suitable for sanding long or large surfaces. The length and width of the belt can be adjusted according to the machine, making it ideal for rapid material removal.

Grinding Wheels: Used for coarse sanding or cutting hard materials such as metal and stone. Made from abrasive particles bonded together, they are highly durable and suitable for heavy-duty sanding.

Power Sanding Tools

Angle Grinders: Versatile tools suitable for hard materials like metal, stone, and concrete. Equipped with various types of grinding wheels or discs, they can perform sanding, cutting, and polishing operations. Commonly used in construction, mechanical processing, and automotive repair.

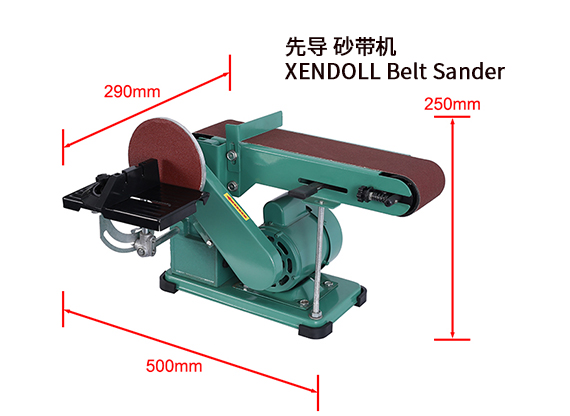

Belt Sanders: Ideal for sanding long or large surfaces. The continuous motion of the belt ensures high efficiency and rapid material removal. Suitable for woodworking and metal processing.

Vibrating Sanders: Designed for sanding complex shapes or small surfaces. The sandpaper vibrates at high frequency, making it suitable for fine sanding. Commonly used in woodworking and model-making.

Polishers: Generally used for surface polishing to achieve a smooth and glossy finish. Equipped with polishing pads and compounds, they are suitable for polishing surfaces of automobiles, metals, and wood. Commonly applied in automotive detailing and metal processing.

Classification by Application

Sanding tools can also be categorized based on their specific applications, such as woodworking, metalworking, stoneworking, automotive surface sanding, and furniture refinishing. Selecting the appropriate sanding tool according to specific needs can improve work efficiency and achieve better sanding results.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll

WEB:www.xendolltools.com