Add Date: 2025/3/25 Views: 1

Keywords: # Small CNC Machine Tool, # Desktop CNC Machine Tool, # Small Teaching CNC Milling Machine, # Small Teaching Machining Center, # Desktop CNC Lathe

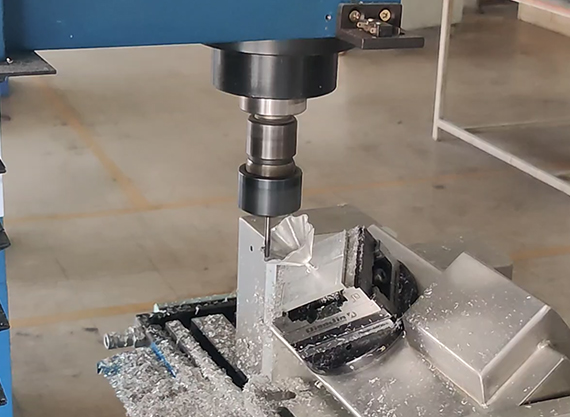

As technology advances, higher demands are placed on the quality and productivity of machinery products, and product updates are accelerating. Thus, CNC machine tool renovation is crucial and has become a key part of industrial development. Milling machines are widely used, mainly for processing surfaces or formed surfaces.

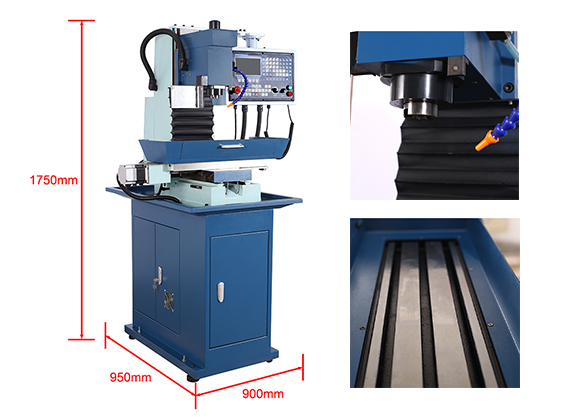

For small processing workshops just starting out, the compact CNC milling machine C31 is a better choice to better control costs. It has a small size and floor area, saving space and consuming less energy than industrial - grade milling machines.

Industrial - grade machine tools are costly, inefficient, energy - intensive, and have relatively low spindle speeds. Micro - mini machine tools were developed to solve these issues. They not only enhance space utilization and reduce costs but also achieve high - speed machining and high - precision motion control due to reduced inertia.

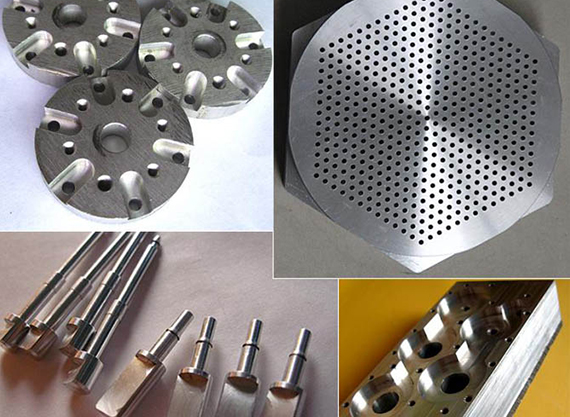

Common small parts include gear shafts, connecting devices, bone screws, and plugs. Although small in size, they require increasingly higher dimensional accuracy, surface quality, and processing efficiency. Therefore, small - part processing demands higher precision, material quality, chip control, stability, and safety in cutting tools.

Milling machines, known for high processing accuracy, good surface quality, and strong adaptability, are widely used. However, different part structures suit different machining methods. For milling machines, the most suitable part structures are as follows.

Planar parts, with basically planar surfaces, are best processed by milling machines. They can efficiently and accurately process large - area planes.

Hole parts, with hole structures, can be machined via drilling or boring on milling machines. Milling machines can quickly and precisely process holes, making them ideal for parts requiring high - precision holes.

XENDOLL C31 Compact CNC Milling Machine

Product Features:

The machine tool body is made of high - quality cast iron, precision ground after super - audio frequency quenching, ensuring machining rigidity, precision, and durability.

It comes standard with an industrial - grade CNC system (other systems optional), with a reserved 4th axis interface for adding a fourth axis to achieve 4 - axis联动.

It is compatible with standard G - codes from FANUC, Mitsubishi, and multiple CAM software (MasterCAM, UG, etc.), and supports powerful B - class macro parsing for easy user - developed motion control programs.

The X, Y, and Z axes use high - precision ground ball screws, with an integrated lubrication system, workpiece cooling system, and electronic handwheel for flexible operation. The CNC system offers various tool - setting methods like automatic centering and tool - setter use.

It has a high - precision spindle motor with G - code - controlled spindle speed.

Other configurations are optional.

For small parts, traditional lathes or milling machines may be limited. Compact milling machines, with high precision, efficiency, and flexibility, are a better choice for quickly processing these parts.

These parts are widely used in mechanical transmission systems, such as motor shafts and gear shafts. Their machining features include high precision, strict surface quality, and high - efficiency processing. Typical workpieces include motor shafts and gear shafts.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll

WEB:www.xendolltools.com