Add Date: 2025/3/13 Views: 1

Keywords: #compact machining center, #desktop machining center, #small 5-axis machining center, #innovative technical skills, #CNC skill development

With the rapid development of intelligent manufacturing, the intelligent CNC technology major focuses on applying intelligent technology. Students will learn the concepts and trends of intelligent manufacturing, and the composition and principles of intelligent manufacturing systems, laying a foundation for future intelligent production. The application of industrial internet and IoT technology in CNC fields is also emphasized. Students will learn to remotely monitor and intelligently manage CNC equipment to boost efficiency and flexibility.

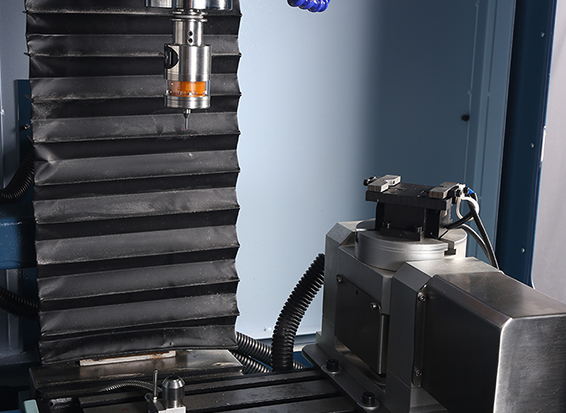

Through internships and hands-on training, students will become proficient in operating CNC machines for part machining. They will also learn maintenance and care of CNC equipment, acquire maintenance and commissioning skills to ensure proper operation, and master quality inspection methods for machined parts to control quality during the process.

Cultivating vocational skills starts with learning. School education offers systematic professional knowledge, while vocational training focuses on practical operation and targeted skill development. Practice is essential in the learning process. Only by applying knowledge in real work can skills be truly mastered and consolidated. Experience can be accumulated through internships, projects, and actual tasks.

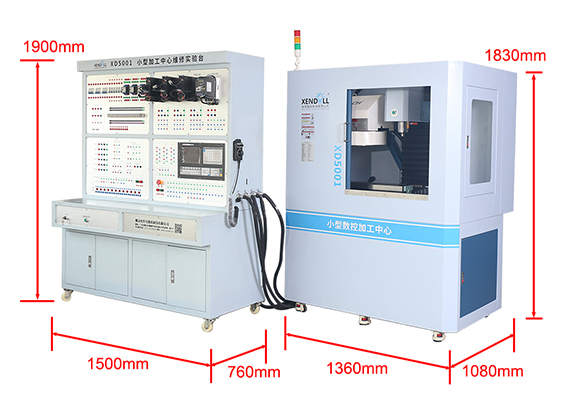

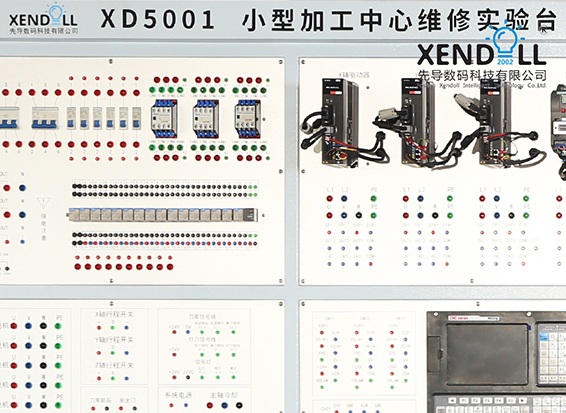

The XD5001 CNC machining center repair lab bench is a multifunctional teaching platform combining mechanical processing, electrical control training, fault diagnosis, and CNC system training. It integrates CNC teaching, principle teaching, operation training, electrical control teaching, and fault analysis for perfect combination of machining centers and electromechanical control.

In today's society, IT and digital capabilities are essential for all industries. College students should focus on developing these skills, including proficiency in office software, information analysis, and data processing. They can enhance their IT skills through computer courses, online learning, and hands-on practice. Additionally, adapting to digital work styles like virtual teamwork and remote working is crucial for vocational skill development.

The application of CNC technology in the information industry, such as CNC system development and maintenance, provides technical support.

The curriculum of intelligent CNC technology ranges from basic theory to advanced techniques. Through systematic learning and practical training, students will be capable of working in CNC machining, programming, equipment maintenance, and management, supporting the automation and intelligence of manufacturing.

Beyond theoretical and skill learning, the major emphasizes the development of practical and innovative abilities. Students will use training bases to apply theoretical knowledge and build hands-on skills. Project-driven teaching is also key, using real projects to guide knowledge application and foster comprehensive abilities and innovative thinking. This practical and innovative approach helps students better meet future workplace demands and challenges.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll

WEB:www.xendolltools.com