Add Date: 2024/8/1 Views: 50

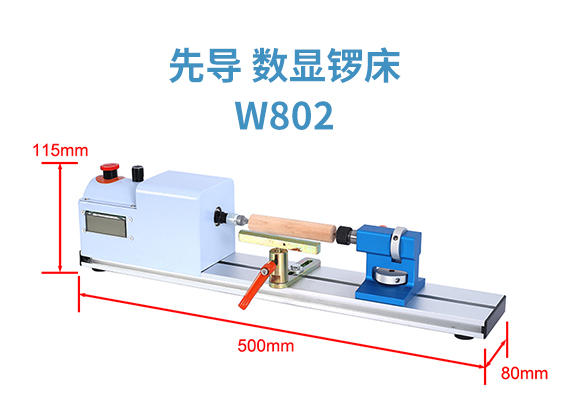

Keywords: # Small precision lathe, # Small machining lathe, # Small tool machine, # Desktop precision lathe, # Desktop CNC machining lathe

Maker small machine tools are small machine tools designed specifically for maker, innovation studios, campus technology production, and CNC teaching scenarios. These machine tools typically have a small processing range and relatively simple functions, making them suitable for beginners or users engaged in small-scale processing. They are compact in structure, easy to operate, and relatively affordable in price.

The introduction of maker small machine tools enables students to personally operate the machine tools in the workshop, and carry out practical activities such as component installation and assembly. This hands-on learning approach helps deepen students' understanding of mechanical manufacturing, process flow, and other aspects, thereby enhancing their practical operational abilities.

Maker small machine tools are designed to meet the needs of miniaturization and convenience. Therefore, their structure is relatively compact, occupying a small area. In terms of configuration, they may pay more attention to usability and economy, such as using a relatively simple CNC system, smaller spindle power, and processing range.

Maker small machine tools are usually designed as desktop or miniaturized, occupying relatively small space and making them easy to use in offices, laboratories, or home environments, without causing excessive burden on the workspace.

During the use of maker small machine tools, students can unleash their imagination to design and create unique works. This creative process can stimulate students' curiosity and thirst for knowledge, cultivate their innovative thinking and creativity.

Through the use of maker small machine tools, students can gain a more intuitive understanding of the production processes and technical requirements of modern industry, thereby increasing their awareness of the profession and society. This understanding helps them better plan their future development direction.

Although maker small machine tools do not have as strict temperature and humidity requirements as large industrial machine tools, they still need to maintain certain temperature and humidity conditions to ensure their normal operation. Excessive or insufficient temperature and humidity may cause damage to machine tool components or a decrease in machining accuracy.

Maker small machine tools generate certain noise and vibration during operation, but compared to large machine tools, their noise and vibration levels are lower. And it will generate pollutants such as metal chips and dust during the processing, which will deposit on the surface of the machine tool and the surrounding environment, causing a certain impact on air quality.

Maker small machine tools usually use advanced energy-saving technologies and environmentally friendly materials, with low energy consumption and minimal environmental impact. However, attention should still be paid to conserving electricity and reducing waste generation during use to achieve sustainable development.

With the rapid development of technology, numerical control technology has gradually penetrated into various industries. The use of maker small machine tools enables students to be exposed to and adapt to this technological change in advance, preparing them for future employment and entrepreneurship.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll