Add Date: 2024/7/30 Views: 49

Keywords: # Small precision lathe, # Small machining lathe, # Small tool machine, # Desktop precision lathe, # Desktop CNC machining lathe

A small precision lathe is a specialized machine tool used for machining various precision components. It is mainly used for machining various rotating surfaces and end faces of rotating bodies, such as turning inner and outer cylindrical surfaces, conical surfaces, ring grooves, and forming rotating surfaces, turning end faces and various commonly used threads. It is particularly suitable for machining metal and non-metal parts. It is usually equipped with advanced control systems and precision cutting tools to ensure machining accuracy and efficiency.

Small precision lathes are widely used in various fields due to their high precision, versatility, and relatively small footprint. For example, in the manufacturing industry, small precision lathes are commonly used to produce components that require high-precision machining, such as key parts in industries such as aerospace, medical equipment, and precision instruments. These components typically have strict requirements for dimensional accuracy, surface roughness, and shape accuracy.

In the mold industry, small precision lathes can be used to process key parts such as cavities, cores, and sliders of grinding tools. The accuracy of grinding tools directly affects the quality and production efficiency of products. Therefore, using small precision lathes can ensure high-precision machining of molds.

Small precision lathes are often used in teaching and practice in mechanical engineering due to their easy operation and learning. In the field of scientific research, researchers also often use small precision lathes for material testing, process exploration, and other actions.

Small precision lathes are an economical and practical choice for start-up companies and small workshops with limited funds and space. They can meet basic processing needs while reducing investment and operating costs.

Small precision lathes have five major characteristics: high precision, meeting the machining needs of precision components; Multi functional, capable of performing various machining operations such as drilling, expanding, and reaming; Compact structure, small footprint, suitable for various limited working environments; Easy to operate, simple to operate system, easy to pick up and operate; Good stability, using high-quality materials and advanced manufacturing processes, with good stability and reliability during the processing.

The main feature of the product is stepless speed change. Small precision lathes have stepless speed change function and can adjust the speed according to processing needs; The complete set of metal exchange gears improves the durability and accuracy of the lathe; Provide a stable tool installation platform to ensure machining accuracy.

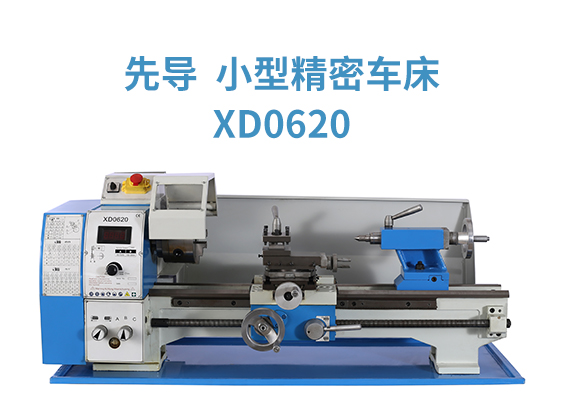

XENDOLL small precision lathe is a machine tool equipment with diverse functions, convenient operation, and compact structure, widely used in multiple fields. When making a purchase, it is recommended to consider and compare comprehensively based on actual needs.

Welcome to our video link:

YouTube: Xendoll

Facebook: Xendoll